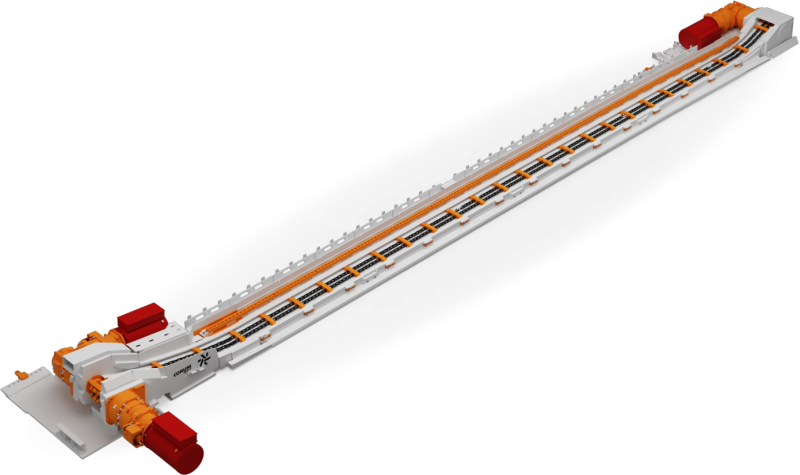

Designed for operation in high-load longwalls in flat and inclined 1.4-3.2 m coal seams, advancing along the strike at the angles up to 35° and down-dip and up-dip at the angles up to 10°. Provides efficiency of up to 24 tons per minute.

High shearer total installed power 848 kW in minimal dimensions and length 9.35 meters along the axes of cutting drums, allow using it in especially difficult mining and geological conditions with harshly changing seam hypsometry.

Shearer is made with block construction and placing main units and frequency converter in frame, which ensures an easy access to units for service support, simplifies assembling/dismantling.

КDК500 is equipped with modern visualization software, which allows to control shearer operation in real-time mode, automatically calculate daily output, as well as analyse in details recorded data and figure out causes of efficiency decrease and equipment downtime.

КDК500 is fitted with modern control system that monitors main units load and automatically regulates shearer feeding speed. System controls main operational functions and allows to minimize shearer downtime (providing control automatization, mining recording, connection between shearer and other longwall equipment, transferring data to gateway and/or to the surface).

| Efficiency, t / min | up to 24 |

| Seam thickness, m | 1,4 – 3,2 |

| Rated mains voltage, V | 1140 |

| Cutting drum diameter, m | 1,4 – 1,9 |

| Rated width of cut, m | 0,63 – 0,8 |

| Maximum feeding speed, m/min | 20 |

| Maximum feeding traction force, kN | 450 |

| Length between the axes of cutting drums, mm | 9351 |

| Frame height in the area of roof support, mm | 1146 |

| Total rated electric drives capacity, kW/h | 848 |

| Cutting drum drive | 2 x 375 |

| Feed drive | 2 x 45 |

| Hydraulic block drive | 8 |

| Weight, t | 43 |

Send us a questionnaire

In addition to this product, following services can be ordered:

Facebook

Facebook

YouTube

YouTube LinkedIn

LinkedIn E-mail

E-mail Twitter

Twitter